The advantages of this approach are:

- Extracting fuel cell parameters from test results is a time consuming process, especially for large fuel cell stacks as data processing requirements increase with size. Post processing of data by the test station will save significant time for the users, while providing them with parameters that will assist in the analysis of test results.

- Validation of the test data is critical for reliable testing. Post processing of test data provides opportunities to validate the reliability of test results using mathematical formulations. Such formulations can be created using first principal models that describe fuel cell dynamics, as well as a priori information about the system response.

- For many types of tests, the optimized testing parameters are not known prior to testing, as they are a function of the device under test. Integrating post processing into the test station allows for optimizing the testing parameters in real time based on the obtained data. This enables the development of more efficient testing procedures.

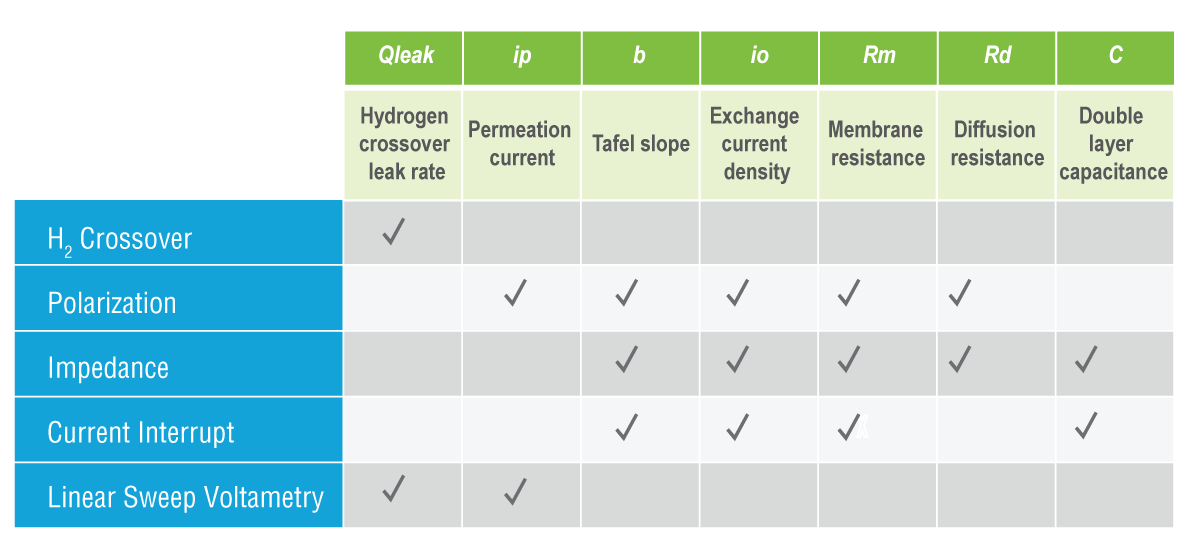

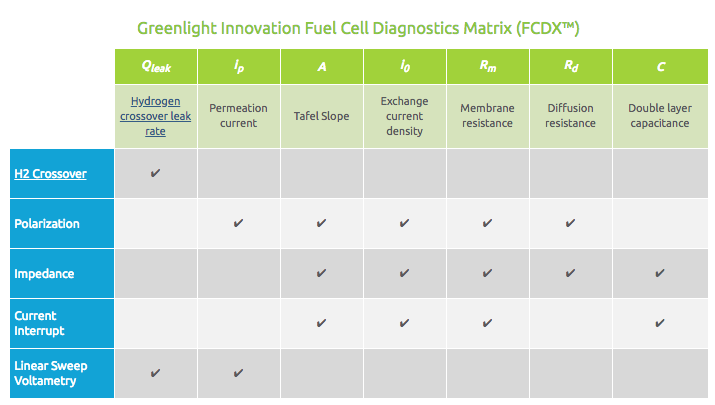

The Fuel Cell Diagnostics Matrix (FCDX™) presented below is a guide to the parameters that each Intelligent Fuel Cell Diagnostic methodology can provide. The rows of the FCDX™ represent the automated algorithms that conduct the testing. These algorithms are embedded in Greenlight’s ‘Emerald’ control and automation software. The columns of the FCDX™ Matrix are the fuel cell parameters that are calculated by each automated algorithm. The first row and column of the matrix are currently linked to the respective white papers that explain them. We will be adding further white papers to other links, as well as rows and columns to the matrix.

If you are interested in being added to the mailing list to obtain updates of the Matrix or have any questions, please email us here.