How Porosimeters Work

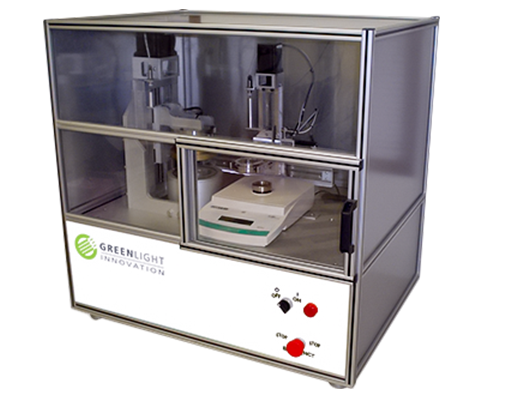

- The sample being tested and the two reference samples (standards) are dried and weighed - then they are saturated under vacuum with a wetting liquid (water, octane, etc.).

- The sample being tested is held in the cup between two reference standards.

- The stack is transferred into the chamber where the reference standards and test sample are brought into contact. The stack undergoes drying and preset conditions of vacuum, temperature and compression.

- After a period of time the stack is removed from the chamber, diassembled and weighed individually.

- The process continues until the stack is completely dry.

- The information gathered on the sample being tested is compared to the reference standards and a variety of data can be received.

The knowledge of porous structure of components of PEM Fuel Cells (membrane, gas diffusion catalytic anode and cathode and gas distribution carbon layers) is important for understanding of mass and heat transfer process inside cells to increase specific energy or power of electrochemical devices in whole.

The following information about porous structures can be obtained by using the Method of Standard Porosimetry (MSP) and Automated Standard Porosimeter:

Proton Exchange Membranes:

- Pore radius distribution curve in real environment (in water) MSP tests using working liquids.

- Adsorption (desorption) isotherms for water in the membrane. This information is important for optimization of water vapour transfer into cells gas chambers.

- Specific surface area. This characteristic is important from the point of view of optimization of membrane's structure to increase its electroconductivity.

Gas Diffusion Catalytic Electrodes & Gas Distribution Layers:

- Hydrophilic and hydrophobic porosity.

- Pore radii distribution curves.

- Specific surface area. It is important for optimization of catalyst layers in electrodes catalyst.

- Distribution of water vs. capillary pressure. This information is important for optimization of Water Management.

- Contact angle vs. pore radius etc.

Distribution of water/electrolyte between components:

Calculation of distribution of water between all components of the Fuel Cell in dependence on total water content can be produced using the results of porosimetric measurements of each component.

For more information, or to request a quote please contact our sales team: sales@greenlightinnovation.com